Specialty Inks

- Products by Category

- Specialty Inks

With our specialty print coatings, any offset printer can offer their customers more than a flat print. Creating great art and amazing prints is only limited to printer and artistic imaginations. Just let us help you with the glitter, pearlescent, metallic, texture, scratch-off or glow in the dark inks, as well as UV flood or spot coatings. Impro excels at high-quality, high-opacity scratch-off printing for offset printers.

Glitter

Screen  printing with glitter inks can add unique value for customers who want special effects that sparkle and shine. You can choose glitter in many different sizes of flake, measured in hex, or the size across the hexagonal flake in fractions of an inch. The size you use will be determined by the design you want to print. A larger flake will catch more light and create a shinier effect, while it will require a coarser mesh screen for the flakes to pass through. This makes larger flakes unsuitable for finer details. A smaller flake won’t catch as much light and the glitter effect won’t be as vibrant, but you can print it through a higher mesh-count screen to capture smaller details.

printing with glitter inks can add unique value for customers who want special effects that sparkle and shine. You can choose glitter in many different sizes of flake, measured in hex, or the size across the hexagonal flake in fractions of an inch. The size you use will be determined by the design you want to print. A larger flake will catch more light and create a shinier effect, while it will require a coarser mesh screen for the flakes to pass through. This makes larger flakes unsuitable for finer details. A smaller flake won’t catch as much light and the glitter effect won’t be as vibrant, but you can print it through a higher mesh-count screen to capture smaller details.

Pearlescent

Pearlescent

Metallic

Metallic special effects printing is

Textures

We use

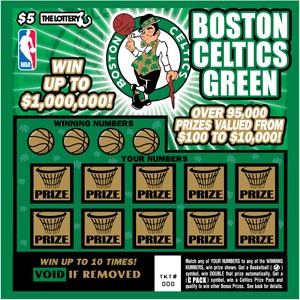

Scratch-off

==> Impro excels at printing high-quality, high-opacity scratch-off panels for the offset printing industry. Highlights include:

-

-

- Very low spoilage

- Security guaranteed

- Quick turnaround

- Comes in silver and gold

- Can be over-printed with other colors

-

Glow In The Dark

Glow in the dark ink printing creates a glowing effect in the dark when charged by light. We mix special chemicals called phosphors into the ink, causing it to absorb energy and re-emit it as visible light. They are best when used on white or light-colored substrates. The glow-in-the-dark ink is light sensitive. It must be exposed to or “charged” under normal light before being used in the dark. Typical glow-in-the-dark screen printing ink comes in whitish or clear formulas. These inks produce a green glow, but many other color options are also available.

UV Flood/Spot Coatings

UV coating, or ultraviolet coating, is a very glossy, shiny liquid coating which we apply to a printed paper surface. We cure it on a printing press or with a special machine using ultraviolet light. The coating hardens when we expose it to the ultra violet radiation. Choose a UV coating when you want to highlight or protect printed materials. Try it on book covers, the point of purchase displays and advertising material. We offer both matte and gloss UV spot and flood coatings.

Choose Impro and we’ll improve your image!

Give us a call at 847-398-3870 today!